Make a Cigar Tube Circuit Tester

| Project Name: | Cigar Tube Circuit Tester |

| Project Description: | Learn how to make a low voltage DC circuit tester. |

| Project Difficulty: | Easy |

| Project Note: | This project uses a soldering iron and heat gun. Please use caution when using hot items. |

In this project, we’re going to make a low voltage DC circuit tester — like the ones you get for testing automotive circuit points — but the one we will be making we’ll also be able to easily use on smaller circuit points, such as for breadboard prototype circuits and PCB circuits. This kind of project is super-easy and is a great way to learn how to use basic electronic components to make something useful.

What’s a Circuit Tester?

A circuit tester or automotive test light is a tool used to identify whether there’s a voltage supplied to a point in a circuit, such as in an automobile’s circuit, or some other low voltage circuit.

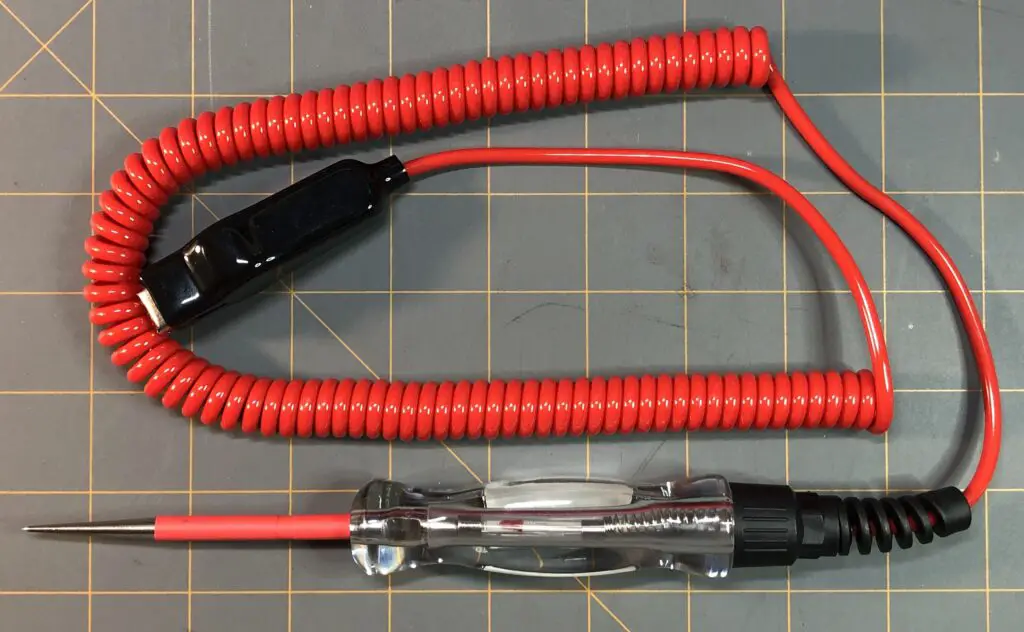

A basic circuit tester that is commonly used by mechanics and DIYers is a handheld device that kinda looks like a screwdriver, except that it has a large pointy probe at the end of it and a wire with an alligator clip attached to it on the end of its handle. The circuit tester handle has a light source within it, such as an LED, that lights up when the circuit tester is in contact with a circuit that has a voltage source across it.

To use a circuit testing tool, such as the test light shown above, you connect the alligator clip from the handle of the tool to a clean grounding point on the circuit to be tested, then touch an area of the circuit with the probe end. When a connection is made from ground to a point in the circuit that has a voltage supplied to it (usually between 6 and 24 volts DC), the circuit tester handle will light up, showing the user a visual sign that there is power getting to the point being tested.

The following links will direct you to people who have demonstrated how to use a circuit tester on vehicles, and each have done a far better job in doing so than I could have. I highly suggest that you watch each video to learn more of the circuit tester:

- JoeCanDoIt: How to Use an Automotive Test Light – Quick and Easy

- Bill Of All Trades: How To Use An Automotive Circuit Tester Pen

- Scotty Kilmer: How To Find Electrical Shorts

- 4DIYers: How to Use an LED Test Light

The circuit tester shown in the image above has no mechanical parts (except for the alligator clip), and does not require a power source, like a battery, to use it. The LED in the handle of the circuit tester is lit up by the power source of the circuit being tested.

The Need for a Circuit Tester

Sometimes, people find a need for a circuit tester to trace electrical connections under the hood of their vehicle. Maybe they realize that something just isn’t functioning properly and they need to see if power is even getting to the device. Personally, I needed one not long ago to test some horrendous wiring that was done on an old Ford 600 Series tractor (Model 640) I recently acquired.

When I would turn the ignition switch on for my Ford 600 tractor and press the starter button, nothing would happen. I suspected a bad starter button, but was unsure, and was not confident in the previous owner’s wiring capabilities, since they had converted it to a 12V system themselves (them old tractors used to run on a 6V system that used a positive ground instead of a negative ground).

I’ve worked on a lot of different vehicles in my time, but had never found the need to use a circuit tester until I came across my newly acquired old Ford tractor, so I ended up purchasing one so that I could test out some points throughout the tractor.

The circuit tester I purchased is the Winamoo Heavy Duty Automotive Test Light, that claims to have a test voltage range of 6VDC to 24VDC (VDC stands for “volts DC” or “volts direct current”). Its equipped with a 135 inch coiled PU red test lead cable with a pretty beefy and durable flat-head alligator clip. It even came with a spare LED encased in a fuse capsule, which is pretty cool.

Where The Design Came From

Well, before I bought my own tool, the design basically came from what I had observed from other people using a circuit tester. I saw that when someone connected the ground end alligator clamp on a grounding bolt on a car chassis, for example, then touched the pointy probe end on the handle of the tool to where power should be, that the light within the handle would light up.

So, I thought to myself, “Hey! I could probably make a circuit tester myself!“, based on those observations. I also figured that if I were to make my cigar tube circuit tester that I ought to make it with a thinner or smaller probe so that I may also use it on smaller circuits for electronics or robotics projects — if the need were ever to arise.

So, I began making a test circuit on my breadboard (as described in the Prototyping the Circuit section below), touched the jumper wire probes across a 9 volt battery, and viola, the LED lit up on my test citcuit! Now, all I needed was to find something that I could use as a handle to hold a probe and other electronic components in — that’s when I remembered that I had a bunch of old cigar tubes I’ve kept around for just this kind of project to use one for!

I’m not a smoker, but I did work at a golf course many years ago where people would smoke cigars, and lots of them. They’d leave their cigar tubes strewn about the golf carts when they’d drop them off at the club house. So, when I’d take the carts to go get them cleaned and charged up, I’d just keep the cigar tubes thinking I could use them for future projects — and now, I finally am! YESSSS!

If you’re under the age 18 in the U.S., you can find cigar tubes from either your dad, grandpa, uncle, or much older brother who is over 18. If you’re of the age 18 and over in the U.S., and not a smoker — and don’t work at a golf course — you can find cigar tubes from either your dad, grandpa, uncle, a friend who smokes or probably even a smoke shop that sells cigar tubes.

Differences in Design: Cigar Tube vs. Store Bought Circuit Tester

Store Bought Circuit Tester

The design of the store bought circuit tester I have has only one LED within the handle that lights up when you have the probes touching across a voltage potential. The LED will light up in either direction as demonstrated in the video below:

- The store bought circuit tester is specifically designed for automotive use.

- The store bought circuit tester has a large pointed probe at the end of its handle.

- The store bought circuit tester is rated for a test voltage range of 6VDC to 24VDC.

- I actually tested it as low as 2V from my voltage supply and the LED in the handle was still able to light up.

VDC stands for “volts DC” or “volts direct current”

Cigar Tube Circuit Tester

The design of the cigar tube circuit tester has two LEDs within the handle that lights up to tell you which direction or orientation you have the probes connected across a voltage potential:

- The white LED lights up when the paper clip probe is touching the positive point in a circuit and the alligator clip is connected to ground or a negative point in a circuit.

- The red LED lights up when the paper clip probe is touching the negative point or ground in a circuit and the alligator clip is connected to a positive point in the circuit.

Below is a video demonstrating the red and white LEDs lighting up on the cigar tube circuit tester based on probe orientation on the circuit:

“I also figured that if I were to make my cigar tube circuit tester that I ought to make it with a thinner or smaller probe so that I may also use it on smaller circuits for electronics or robotics projects — if the need were ever to arise.“

- The cigar tube circuit tester is designed for either automotive, breadboard prototype circuits, or PCB circuits.

- The cigar tube circuit tester has a durable, thin pointed probe at the end of its handle – perfect for smaller circuit points!

- The cigar tube circuit tester is rated for a test voltage range of 6VDC to 24VDC.

- I actually tested it as low as 3V and both LEDs were still able to light up. I also tested at 2V on my voltage supply, like the store bought tester, but neither LED was able to light up – this is probably because of the use of diodes in the cigar tube circuit which have a forward voltage drop of around 0.7V.

NOTE: The diodes in the cigar tube circuit tester may be totally unnecessary, but I wanted to add them to emphasize the importance of current control in a circuit and possibly add a little extra “protection” for our LEDs in the circuit. The cost of diodes are pennies, so they don’t cost much and the ability add a little extra learning tool in this project is a plus for all of us whose tried this neat project. You can choose to exclude the diodes if you’d like, and your circuit should still work just the same – you’d just have the LEDs as your only diodes in your circuit then! 😉

Let’s Be Methodical

I like to be very methodical about things, so we’ll go step-by-step — in detail — on the entire build of this project: the parts we’ll need, why we’re using them, how to connect them, how they work, and more! First, we’ll start with the following parts list:

Parts List

| Item | Quantity | Description |

| Plastic Cigar Tube w/ Cap | 1 | This will be our tool handle and contain the electronics and probe within it. |

| 2 Inch Paper Clip | 1 | This will be used as our probe. |

| Alligator Clip | 1 | This will be used as our grounding clip. |

| 1.2 kΩ Resistor | 2 | These will be our current limiting resistors. |

| 1N4001 Diode | 2 | These will be used to block the flow of current to certain directions and allow the flow of current in other directions within our circuit tester circuit. |

| Red LED 5mm Diffused | 1 | This will be an indicator light for our test probe showing reverse polarity. |

| White LED 5mm Diffused | 1 | This will be an indicator light for our test probe showing correct polarity. |

| Black 18 Gauge Silicone Wire Stranded | 3 feet | This wire will be used as our grounding wire that will attach to our PCB circuit board on one end and to the alligator clip on the other end. |

| 2cm x 8cm Prototype PCB Board | 1 | We will actually cut this PCB to a smaller size. This will be how we solder our components together to then insert them within the cigar tube as one piece. |

Tools Used in Project

| Item | Description |

| Solder Station | The soldering station I currently use is a Yaogong YG8586. It is equipped with a soldering iron with holder, and a rework heat gun. |

| Solder | I used the MG Chemicals rosin core leaded solder with a diameter of 0.025” — Sn63/Pb37 |

| Soldering Iron Tip Cleaner | I use an Aoyue soldering iron tip cleaner with brass wire sponge, but in the past I just used a regular damp dish sponge to clean my solder tips. |

| Wire Stripper | The wire stripper I used for this project was a TNU-U model TU-5023, which is just a generic wire stripper. Any ole’ 20-30 AWG wire stripping tool will do or you can use your pocket knife, like I used to do back in the day. |

| Tweezers | I use an ESD-15 curved tip tweezer all the time for my projects, not just this project. They’re very handy. |

| WorkPro Rotary Tool and Kit | I used my WorkPro rotary tool to drill the holes needed for the plastic cigar tube handle of the circuit tester. |

(Optional) Breadboard Prototyping Parts List

| Item | Quantity | Description |

| Solderless Breadboard | 1 | You can either use an 830 point or 400 point breadboard for testing purposes. |

| Jumper Wires | Multiple Miscellaneous Sizes | We use these to make solderless connections to our components on the breadboard. |

Prototyping the Circuit

NOTE: Prototyping your circuit is optional, but recommended! Try it out!

Before taking our parts and haphazardly soldering them together on our PCB prototype board, it’s good practice to first “dry-fit” our components — or temporarily put together our circuit on a breadboard.

If you need to — you may check out our Breadboard Basics page to understand the breadboard and how to use one.

You can skip this part if you’d like and go straight to the solderable PCB prototype board build for this project below.

Steps 1 – 6: How To Prototype The Cigar Tube Circuit Tester

The following is a step-by-step process on how to put your components together on a breadboard to test to see if your circuit works before placing them permanently onto a solderable PCB prototype board.

I will be using a 400-point breadboard for demonstration purposes, because they’re smaller and perfect for our basic and simple circuit here that only has a few components.

Note that I refer to columns and rows of the breadboard in the following steps. The following images of the breadboard show it laying horizontally, not vertically, and so, the columns appear to be rows and rows appear to be columns. This may seem confusing for the uninitiated, but it’s only because of the orientation of the breadboard in the images. Please refer to our post on breadboards and how to use them here if you’re unfamiliar with using them.

- Installing the Diodes: As you can see from the image below, I’ve started off with placing the two diodes onto the breadboard. Diode (D1) is placed at points d10 and f10, with its cathode end (the gray mark) facing down row 10 through columns a to e, as shown by the purple arrow. Diode (D2) is placed at points d19 and f19, with its cathode end (the gray mark) facing down row 19 through columns f to j, as shown by the teal arrow.

- Connecting the Resistors: Referring to the image below, I’ve placed a 1.2kΩ resistor (R1) at point c10 on the breadboard — in-line with the cathode (-) of diode D1 — and the other terminal end of resistor R1 at point c14. Another 1.2kΩ resistor (R2) is placed at point c19 on the breadboard — in-line with the anode (+) of diode D2 — and the other terminal end of resistor R2 at point c16.

Downloadable Resistor Color Codes Chart

- Connecting the LEDs: In the image below, the white LED’s anode (+) is placed in-line with the resistor (R1) in row 14 at point a14 on the breadboard, and its cathode (-) is placed in a point on the negative supply column on the breadboard. The red LED’s cathode (-) is placed in-line with the resistor (R2) in row 16 at the point a16 on the breadboard, and its anode (+) is placed in a point on the negative supply column on the breadboard. Note that the orientations of the white and red LEDs are opposite each other. Be sure that you’ve placed each LED in their correct orientation as previously described.

- Connecting the Jumper Wires: As you can see in the image below, I’ve placed a small orange jumper wire leading from a point on the positive supply column of the breadboard to point j10 on the breadboard – a point on row 10, in-line with the diode (D1) that we’ve placed on the breadboard previously. I’ve also placed a larger orange jumper wire that goes from point i10 to point i19, each point in-line with the rows of the diodes D1 and D2, respectively.

- Adding the Probes: Next, we add the probes to our breadboard circuit. As you can see in the image below, I’ve added an orange jumper wire as my positive-side probe, and a black jumper wire as my negative-side probe.

- Testing the Circuit Tester: Now it’s time to test our prototype breadboard circuit! Just grab a 9V battery as a test voltage source and touch your circuit probes to the battery terminals. Looking at the video below, you’ll see that if the orange jumper wire probe touches the positive terminal of the battery and the black jumper wire probe touches the negative terminal of the battery, then the white LED lights up. If the probes are switched across the battery terminals, then the red LED lights up.

4 Checks to Troubleshooting Your Breadboard Prototype Circuit

If your LEDs did not light up or are dim in your breadboard circuit, let’s perform a troubleshoot to see what may be the issue:

- Check Voltage Source: For our circuit tester, we used a 9V battery as our test voltage potential. If you are using an old or depleted 9V battery for testing purposes, then this may be the reason why your LEDs do not light up. If the voltage potential of the 9V battery you’re using is too low, then there may not be enough “juice” to light up your LEDs bright enough on the circuit tester. To check your battery voltage using a multimeter you can go to our General Guide to Setting up a Multimeter section here. Try obtaining a new battery or, if you have one available to you, use a power supply and set it to a voltage range of 9V-24V, for best results.

- Check Diode Orientation: In our circuit tester circuit, we used two diodes to control the flow of current. Diodes must be oriented correctly, otherwise you may be blocking the flow of current instead of allowing the flow of current. Check that you have oriented your diodes correctly, as shown in the simulation circuit above, in the circuit diagram under “Video Build of The Circuit on a PCB Board” below, or have a look at the diode orientation image below. Refer to step 1, “Installing the Diodes” above if you are still unsure.

- Check LED Orientation: Make sure you have your LEDs in the correct orientation. If you need help with this, check out our Basic Electronics: LEDs page under the How to Use an LED section of the page here to learn proper LED circuit orientation.

- Check Circuit Connections: Make sure that all components are connected properly. Refer back to the images in the steps above to reassure yourself. If you need to — you may check out our Breadboard Basics page here to understand the breadboard and how to use one.

Video Build of The Circuit on a PCB Board

Now, let’s get to building our permanent circuit for our Cigar Tube Circuit Tester. We’ll first need to cut our PCB to size, then we’ll need to decide where we want to place all our components on the PCB board and where we’ll make our positive and negative probe connections on the PCB.

You can choose how you want your placement of all the components on your own PCB board — or you can follow along with how I did my own — just be sure to connect all the components properly as how I’ve described in the breadboard test build and the circuit diagram provided below:

Video Build – Part 1

Video Build – Part 2

Conclusion

Now that you’ve built this simple circuit successfully, you’re now well equipped to start designing and making your own simple circuits. In this project, you learned how a circuit works, how to include some diodes and LEDs in a circuit, how to perform simple circuit troubleshooting, and you’ve gained some soldering skills! You’re that much closer to your goals!

If you have any questions, leave them down in the comments or follow us on any of our socials and talk to Motbots there. Remember to stay motivated and keep at it!

Frequently Asked Questions

Q1.) Why are my LEDs not lighting up?

- The following are a few possibilities why your LEDs may not be lighting up:

- Improper LED orientation: Make sure you have oriented your LEDs correctly in your circuit. You can see how LEDs are properly oriented by visiting our post on LEDs here.

- Burnt out or defective LEDs: To check to see if your LEDs have been burnt out or are defective in some way you can use the diode test function on a multimeter or create a simple LED test circuit using the coin cell method here — both of which you can find how to do on our page on LEDs here. NOTE: To perform these procedures, you’ll have to remove your LEDs from the circuit. If you’ve soldered your LEDs you will have to either desolder them to remove them from your PCB board or start over again and build yourself a new circuit.

- Improper resistor value or short circuit: If your LEDs are burnt out, make sure you have the proper resistor values and that the resistors are properly connected in your circuit. Refer to the resistor chart above, if needed. If they are not, you may have a short somewhere in your circuit. Please refer to the how-to video and wiring diagram above under “Video Build of The Circuit on a PCB Board”. Get your downloadable resistor color code chart above.

- Improper wiring or component connection: Your LEDs may not work due to improper connection of components in your circuit. If they are, don’t worry. Messing up is all part of the learning process. We all do it. Please refer to the how-to video and wiring diagram above under “Video Build of The Circuit on a PCB Board” to review how to create this circuit.

Q2.) I don’t have a cigar tube. What else can I use?

- You don’t have to use a cigar tube like the one used in this project to complete this project yourself. You can use whatever you can find — such as a candy tube like the one shown below, a large writing pen or old marker tube, an old barbecue lighter, a wood dowel, a small cardboard tube, or any other tubular items that are easy to work with. Just make sure that whatever you use, that your item’s handle is non-conductive and that it’s easy to work with to be able to drill holes in and contain your components and circuit. Also note that whatever you use, make sure that it’s properly cleaned, that you use caution in whatever you hack, and be safe. Hack whatever you have to make your project work and make it unique!

BONUS Design

The following design is similar to the Cigar Tube Circuit Tester design above, but with some added features, and some missing features too. This bonus design allows you to use a second alligator clip on the positive test probe side, if desired. Another feature to this bonus design is its ability to provide a beep or buzz sound via the attached piezo buzzer on the handle.

Having the capability to have your Cigar Tube Circuit Tester to create an audible noise along with a visual queue with its LED, assures the user that power is being provided to the points being tested in the circuit — especially if a test is being performed in conditions that does not allow the user to see the visual queues of the LED on the circuit tester’s handle, such as in brightly lit or natural light conditions or in tight spaces.

Added Features to Bonus Design:

- Secondary alligator test probe.

- Has a piezo buzzer to alert you of power being provided at test point.

Some missing features in the bonus design of the Cigar Tube Circuit Tester are the diode (D2), resistor (R2), and now, instead of two LEDs (red and white), there’s now only one green LED. This change in design only allows for the test of circuits to be done with the black alligator clip probe attached to a negative ground point. The bonus design circuit tester does not allow for positive ground testing — positive ground tests will not light up the green LED or make the buzzer go off.

Missing or Different Features of Bonus Design:

- Only has one diode (D1), one resistor (R1), and one green LED.

- Does not have the capability to perform positive ground tests, only negative ground tests.

Breadboard Prototype of Bonus Design

Schematic of Bonus Design