Types of Electromechanical Switches and Their Configurations

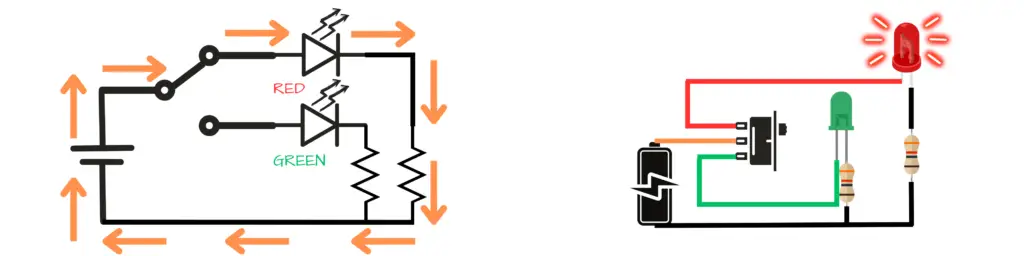

A switch in electronics is a device or component that completes a circuit electrically.

- Electrons flow from a power source through the circuit.

- Electrons need to start from the power source — flow through a circuit entirely — ending back at the power source for the circuit to be complete.

- If a switch is not yet completing the circuit — i.e. the circuit is OFF or the circuit is open at the switch — there is no flow of electrons. In other words, the electrons cannot pass through the switch to get to the rest of the circuit. There’s no current flow.

- Once a switch completes the circuit — i.e. the circuit is ON or the circuit is closed at the switch — electrons are allowed to continue their path along the circuit— tracing their way back to the power source. There is current flow.

An electromechanical switch is a switch that uses a mechanical action that physically manipulates contacts on the switch to either complete a circuit or open a circuit — i.e. the electromechanical switch is manually moved in such a way that its contact turns a circuit ON or it turns a circuit OFF.

You can also learn about electronic switches at our Types of Electronic Switches and Their Characteristics page here.

Electromechanical Switch Types and Configurations

There are several configurations of electromechanical switches. We will review the most common configurations, which include:

- Single Pole Single Throw (SPST)

- Single Pole Double Throw (SPDT)

- Double Pole Single Throw (DPST)

- Double Pole Double Throw (DPDT)

There are also several types of electromechanical switches. We will review the most common types, which include:

- Momentary Push-Button Switch

- Rocker Switch

- Slide Switch

- Toggle Switch

- Limit Switch

- DIP Switch

- Rotary Switch

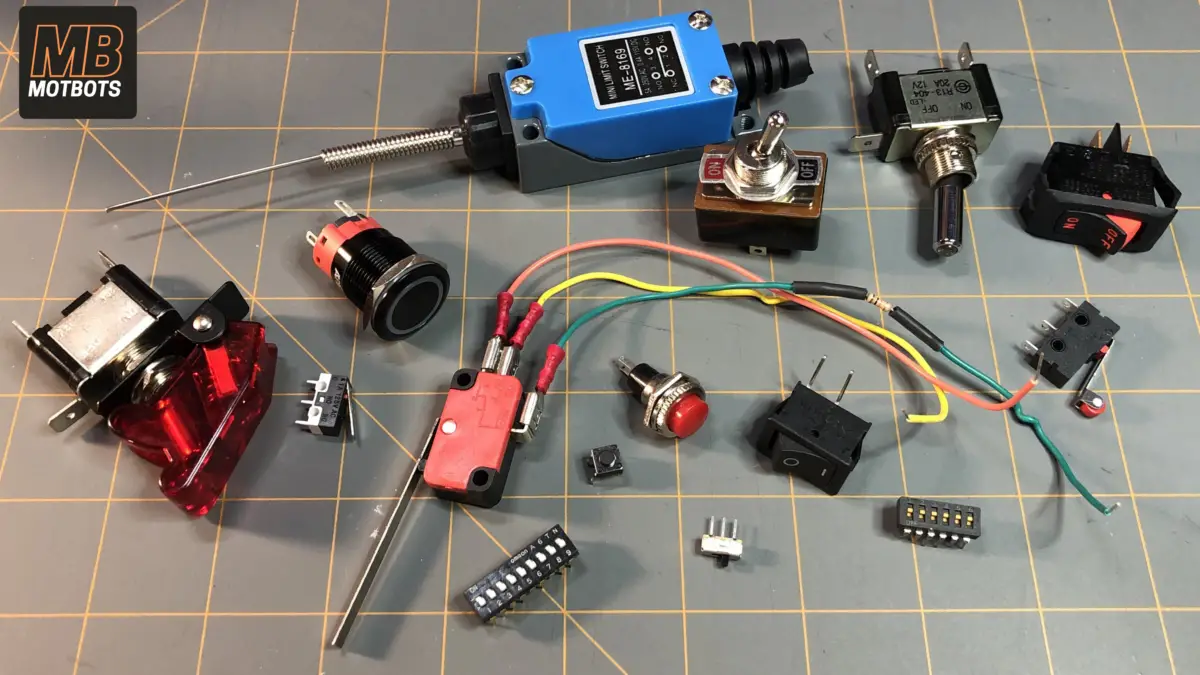

Mechanical switches can come in all shapes, sizes, ratings, configurations, types and colors. We will not go over an exhaustive list of switches here — but mostly give an overview of them and focus only on the most commonly used switches used in industry and by hobbyists.

Electromechanical Switch Configurations

Single Pole Single Throw (SPST)

The SPST switch is a simple ON/OFF switch consisting of two terminals or poles. It has only one input pole and one output pole.

A SPST switch is used for single loop paths in a circuit. This means there is only one way for the switch to control a circuit — and that is by its input and output poles that are only able to connect a circuit through a single path.

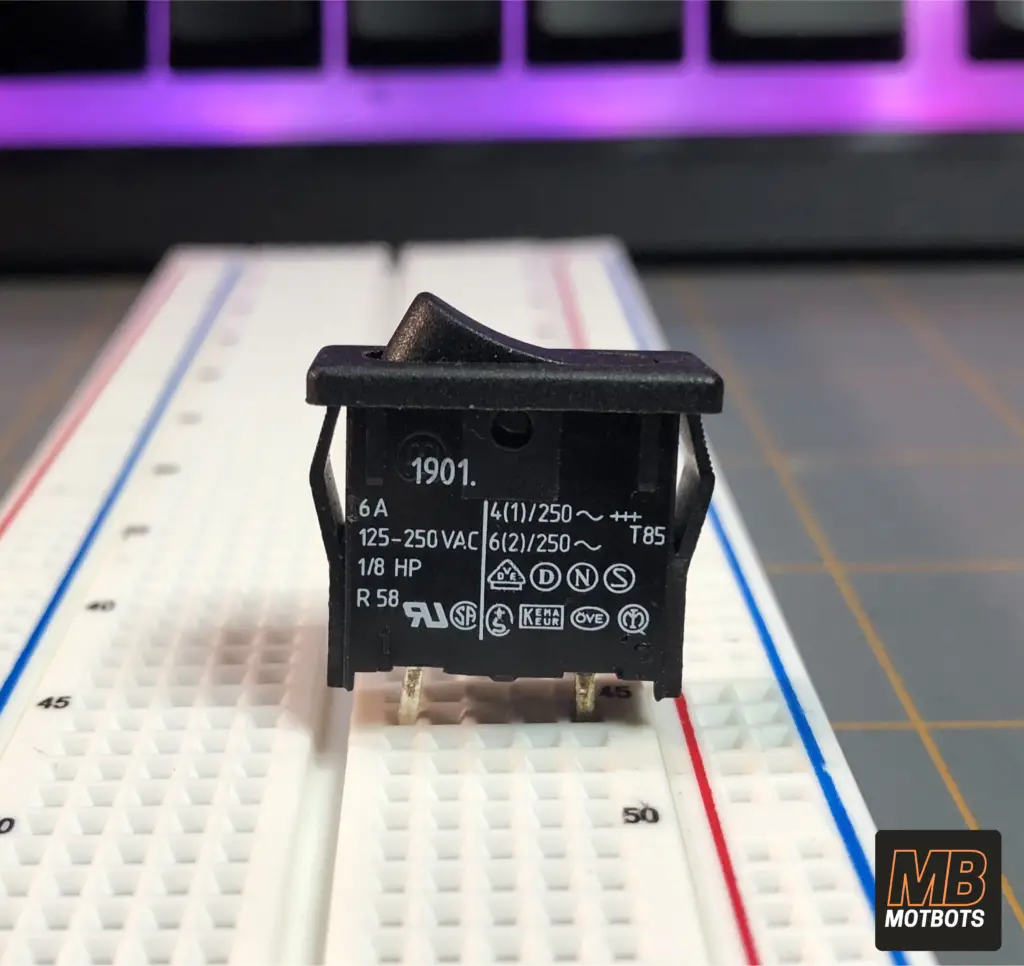

An example of a SPST switch is a rocker switch — commonly used in automobiles, electric bikes, and electronic equipment.

- A SPST rockerswitch is constructed in a way that the (rocker) switch is depressed or “thrown” to one side or the other to either open or close the circuit through its terminals or poles.

- There is an internal contact within the SPST rocker switch that allows the switch to be depressed or “thrown” in either the ON or OFF position.

- The internal contacts of the switch are either made of copper, brass, or even silver to provide reliable conductivity for the circuit.

- When the switch is in the OFF position, neither the input terminal or pole and the output pole of the switch make contact — therefore, making an open circuit.

- When the switch is in the ON position, both the input pole and the output pole of the switch make contact — therefore, creating a closed circuit.

Single Pole Double Throw (SPDT)

The SPDT switch has three terminals or poles — allowing for two separate ON positions. It has only one input pole and two output poles.

One of the poles is the input contact of the switch — whereas the other two are the output contacts of the switch — two separate circuits to turn ON individually.

What this means is that the SPDT switch allows for a sort of branching in a circuit. One position keeps one of the branches OFF in the circuit — the input pole and one of the output poles are not connected — while the input pole and the opposite output pole are connected, completing the corresponding circuit, therefore turning it ON at that branch.

So, while one branch of the circuit is ON via the SPDT switch, the other branch is OFF.

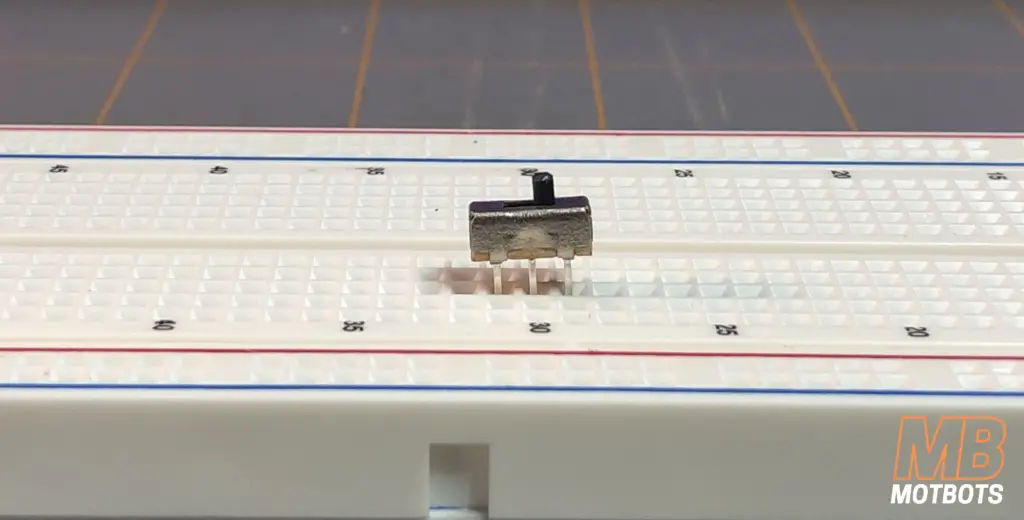

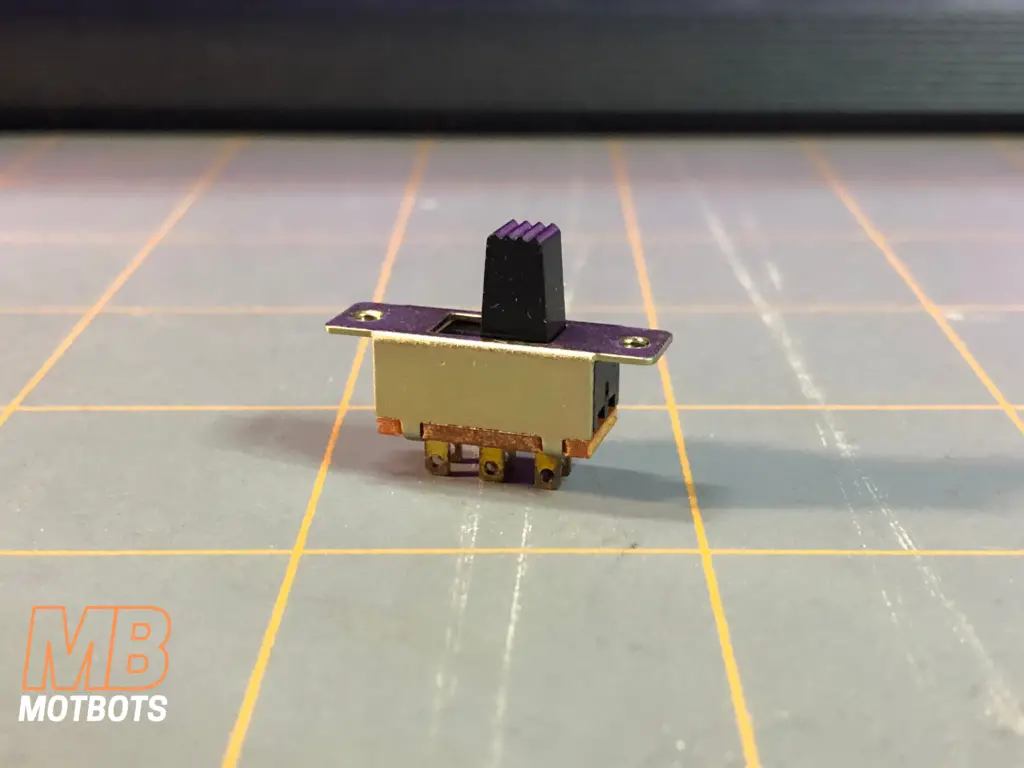

An example of a SPDT switch is a slide switch — commonly used in electronic devices, tools and toys.

- A SPDT slide switch is constructed in a way that it has three terminals or poles. When the slider or actuator is at one side — say the left-side (looking at the picture above) — the contact of the switch makes a connection between the center input pole and the left output pole.

- When the slider or actuator is at the other side — say the right-side (looking at the picture above) — the contact of the switch makes a connection between the center input pole and the right output pole.

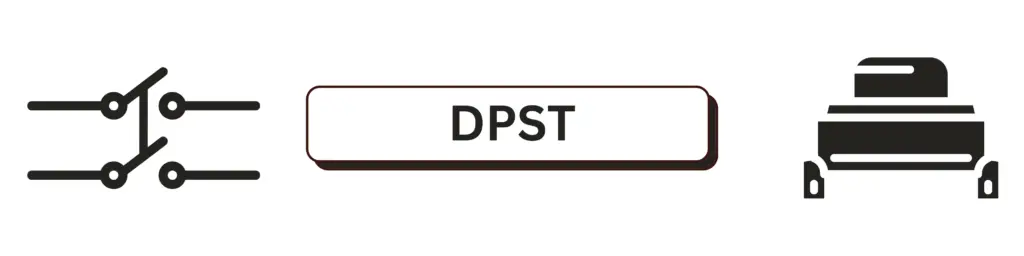

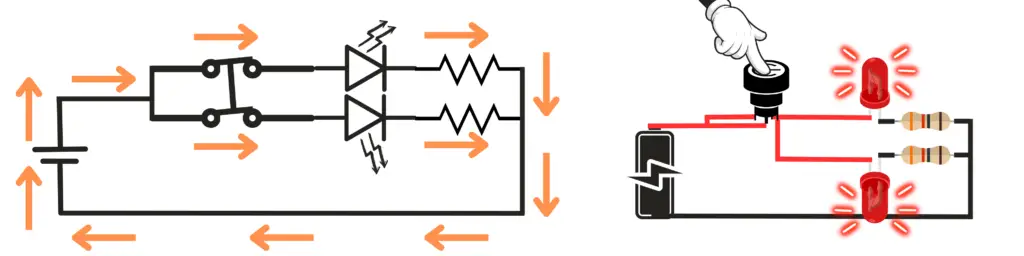

Double Pole Single Throw (DPST)

The DPST switch has four terminals or poles — two input poles and two output poles. What this means is that the DPST switch can essentially control two circuits at a time simultaneously.

You can think of a DPST switch as being two separate SPST switches operating simultaneously. Essentially, each pair of input poles connects to its corresponding pair of output poles.

The way a DPST switch works is that if the pair of input poles of the switch correspond to the pair of output poles, then the switch is closed or ON. The switch connected to the inputs close simultaneously by a single actuator toward the outputs — this creates one ON position that closes the circuit from the pair of inputs poles to the two corresponding pair of output poles — turning both outputs ON simultaneously.

If the pair of input poles of the DPST switch are opened — they open simultaneously by a single actuator — this creates one OFF position that opens the circuit for the two corresponding pair of output poles — turning both outputs OFF simultaneously.

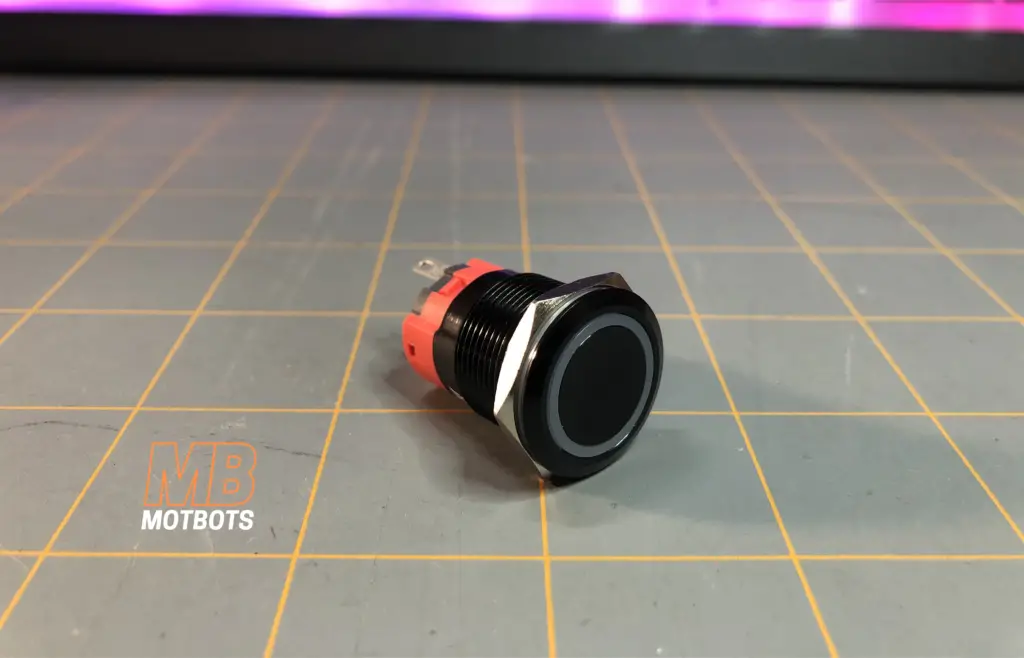

An example of a DPST switch is a push-button switch — commonly used in electronic devices and equipment, as well as in household appliances and toys.

- A DPST push-button switch is constructed in a way that it has four terminals or poles — two input poles and two output poles. There’s a metal contact within the switch that allows for a simultaneous connection between the input and output poles when the push-button is pressed down.

- The contact on the switch is pressed down by the operator — closing the circuit simultaneously and temporarily — therefore, turning the circuit ON between both input and output poles.

- Often times a push-button switch is normally-open — meaning that it does not make contact with its poles — therefore, making the pair of output circuits OFF.

- Not until the normally-open push-button switch is pressed down is the circuit complete — therefore, making the pair of output circuits ON.

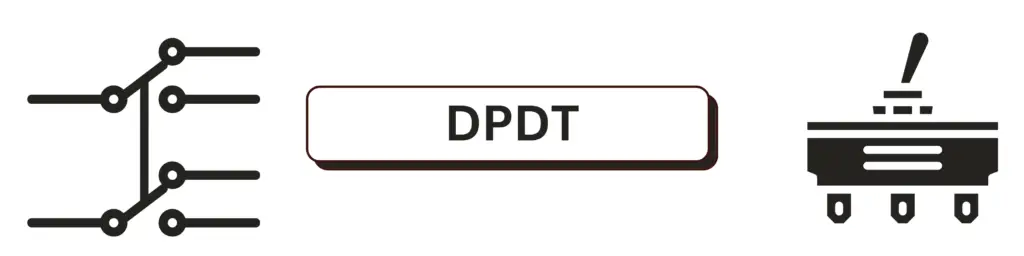

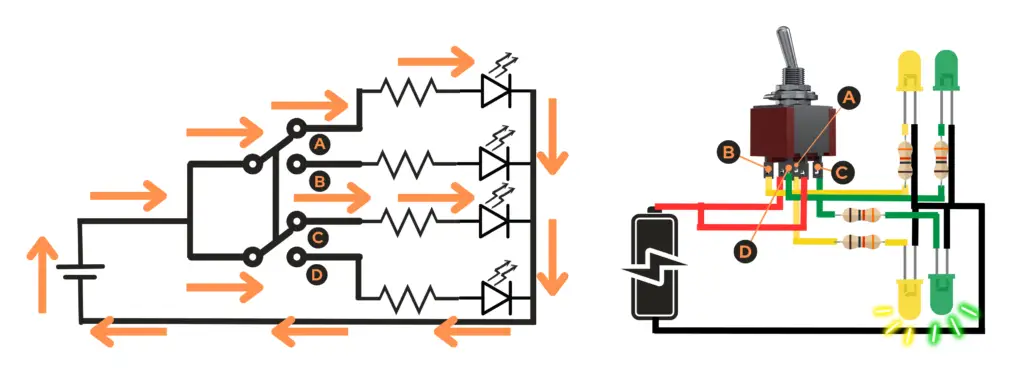

Double Pole Double Throw (DPDT)

The DPDT switch has six terminals or poles — two input poles and four output poles. What this means is that the DPDT switch consists of two ON positions — essentially controlling two separate circuits to either have one output be ON and the other output be OFF or vice-versa, depending on the position of the switch’s actuator.

You can think of the DPDT switch as being two separate SPDT switches operating simultaneously. Essentially, a pair of input poles connect to one set of output poles — turning them ON and leaving the other pair of output poles OFF.

The way a DPDT switch works is that two input poles control one pair of output poles — either output poles A or output poles B.

When the actuator of the switch is one way — say to the left-side (as shown in picture below) — then, the input poles control the pair of output poles A. In this configuration, output poles A are ON for their corresponding circuit and output poles B are OFF for their corresponding circuit.

Now, let’s say the input poles of the DPDT switch are now corresponding to the other pair of output poles B. When the actuator of the switch is set in this configuration— say to the right-side (as shown in the picture below) — then, poles B are ON for their corresponding circuit and poles A are OFF for their corresponding circuit.

An example of a DPDT switch is a toggle switch — commonly used in avionics, marine devices, automobiles, industrial control panels and equipment.

- A DPDT toggle switch is constructed in a way that it uses a lever-type switch to control the configuration of the input and corresponding output poles of the switch.

- A common DPDT type toggle switch has three positions or three switch functions called ON-OFF-ON.

- An ON-OFF-ON toggle switch has a center position, which allows for all circuits to be OFF — meaning there’s no contact between the pair of input terminals and either pair of the output terminals.

- When the ON-OFF-ON toggle switch is flipped to either ON direction, the pair of input terminals correspond to the pair of output terminals that the toggle switch is flipped towards.

Review of Electromechanical Switch Configurations

| Switch Configuration | Total # of Terminals or Poles | # of Input Poles | # of Output Poles | Uses | Example Switch | Example Switch Common Uses |

| SPST | 2 | 1 | 1 | Used when needing to control a single output using one input. | Rocker Switch | Automobiles, e-bikes, electronic equipment |

| SPDT | 3 | 1 | 2 | Used when needing a single input to control either of two separate outputs. | Slide Switch | Electronic devices, tools and toys |

| DPST | 4 | 2 | 2 | Used when needing a pair of inputs to control a pair of outputs, having either both ON or both OFF simultaneously. | Push-Button Switch | Electronic devices and equipment, household appliances and toys |

| DPDT | 6 | 2 | 4 | Used when needing a pair of inputs to control one of either of two pairs of outputs, having one pair of outputs be ON and the other pair of outputs be OFF or vice-versa. | Toggle Switch | Avionics, marine devices, automobiles, industrial controls panels and equipment |

Electromechanical Switch Types

Momentary Push-Button Switch

A momentary push-button switch is a switch that only closes a circuit when its button is pressed — normally opened switch. It momentarily turns the circuit ON when its button is pressed.

A momentary push-button switch can also be a switch that only opens a circuit when its button is pressed — normally closed switch. It momentarily turns the circuit OFF when its button is pressed.

Momentary push-button switches temporarily or momentarily complete or interrupt an electrical circuit.

The are many shapes, sizes, colors, ratings, and configurations of momentary push-button switches — such as SPST, SPDT, DPST and DPDT.

Examples of common momentary push-button switches are doorbells, computer keyboard keys, intercoms, automotive ignition switches, and winch or overhead hoist switches.

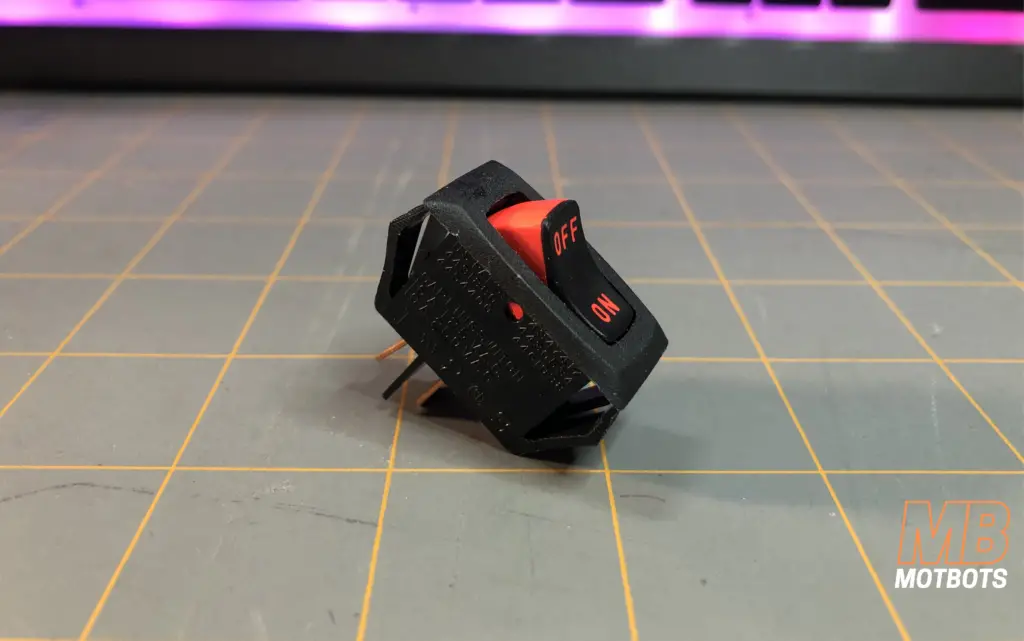

Rocker Switch

A rocker switch is a switch that uses a rocking motion — like a seesaw — to turn the switch ON or OFF.

A rocker switch completes an electrical circuit when it is rocked or pressed in its ON position. The electrical circuit becomes open when the rocker switch is rocked or pressed in its OFF position.

Rocker switches are commonly used as a power supply switch by rocking its switch one way or the other like a seesaw to turn electrical devices ON or OFF.

The are many shapes, sizes, colors, ratings, and configurations of rocker switches — such as SPST, SPDT, DPST and DPDT. Some rocker switches even have built-in LEDs to indicate that a circuit is ON.

Examples of common rocker switches are found in electronics devices and equipment, home lighting switches, home appliances, power tools, and industrial equipment.

Slide Switch

A slide switch is a switch that uses a sliding motion to turn the switch ON or OFF.

The slide switch has an actuator that slides one way or the other to make an electrical connection or an open circuit to its terminals.

The actuator slides or is moved toward one direction of the switch to make an electrical connection — turning the circuit ON. When the actuator slides or is moved in the opposite direction of the switch it makes an open circuit — turning the circuit OFF.

There are many configurations of slide switches — such as SPST, SPDT, DPST and DPDT.

Examples of common slide switches are found in electronic devices and equipment, home appliances, power tools, and toys.

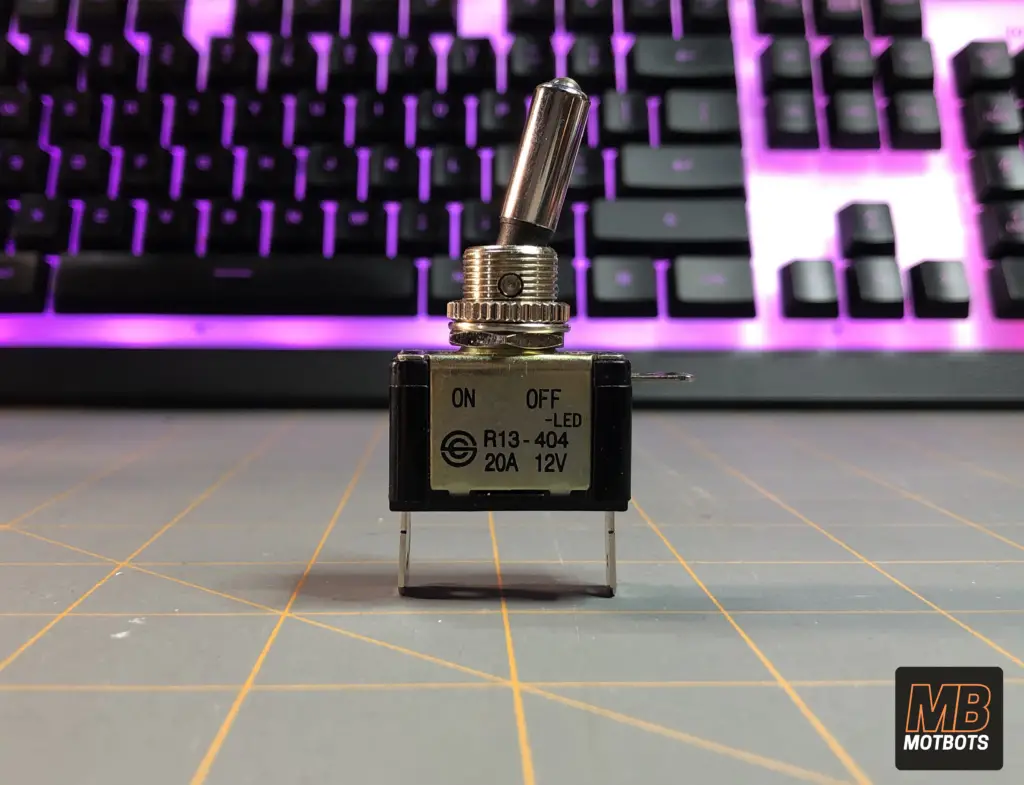

Toggle Switch

A toggle switch is a switch that uses a lever-type actuator to turn the switch ON or OFF.

The toggle switch is manually actuated or moved by its lever actuator or switch mechanism. Toggle switches perform simple ON/OFF operations for electrical circuits.

The toggle switch works much like the rocker switch where the operator moves the switch one direction to close a circuit — turning a circuit ON — or by moving the switch in the opposite direction to open a circuit — turning a circuit OFF.

Toggle switches can come in many different styles and functionalities. There are simple ON/OFF toggle switches where the actuator is moved in either direction to turn a circuit ON or OFF. There are ON-OFF-ON toggle switches where the actuator can be moved in three different positions — a center position as its OFF state and two separate off-center directions for either of two ON states.

The are many shapes, sizes, colors, ratings, and configurations of toggle switches — such as SPST, SPDT, DPST and DPDT. Some toggle switches even have built-in LEDs to indicate that a circuit is ON.

Examples of common toggle switches are found in industrial control panels, industrial machinery, avionics, marine devices, and especially automobiles in the racing industry.

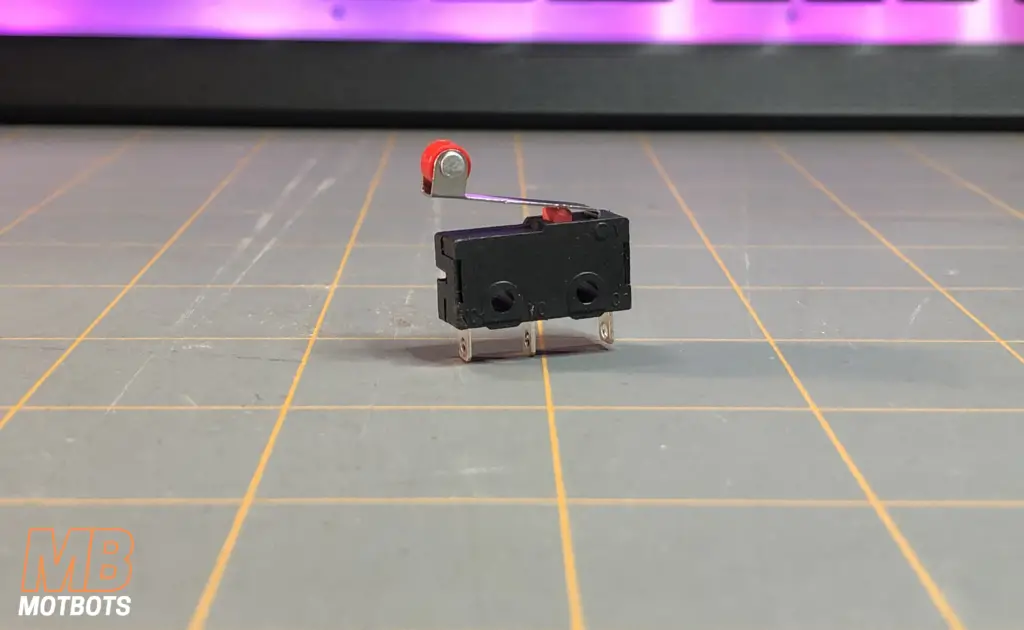

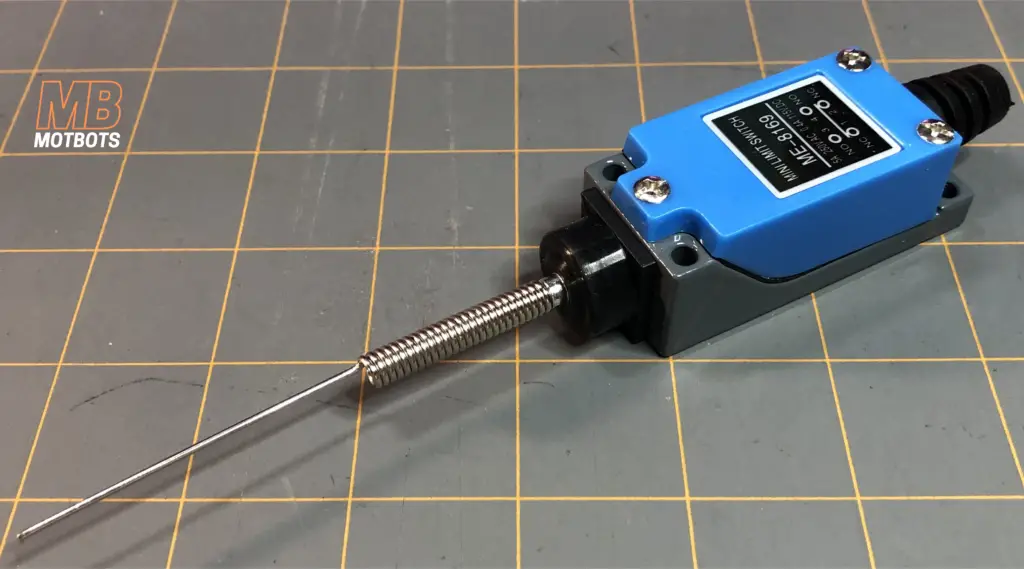

Limit Switch

A limit switch is a switch that uses either a lever, plunger, roller or whisker to press a button to change the electrical connection between its terminals or poles.

Limit switches work similarly to push-button switches in the sense that their actuator is pressed and released to control the action of the switch. Other than that, a limit switch is unique in that they are often times used as a type of electrical-mechanical pressure sensor switch for all sorts of applications.

There are generally four types of limit switches that are classified as lever, plunger, roller and whisker.

A limit switch that uses a lever operates in a way that when an object comes in contact with the lever — the force on it pushes down a button near the lever’s fulcrum turning a circuit ON, for example.

A limit switch that uses a roller operates similarly to the lever type. A roller is often times placed on its lever for moments when the switch comes in contact with something moving. The roller allows the moving object to move freely across the switch without it getting caught and damaging it and/or the switch.

A limit switch that uses a plunger has a plunger-like switching mechanism that when pressed operates the switching action.

A limit switch that uses a whisker usually has a long wire-like whisker as its sensing switch (see image above). When the whisker comes in contact with an object it activates the switch no matter which direction the object comes from.

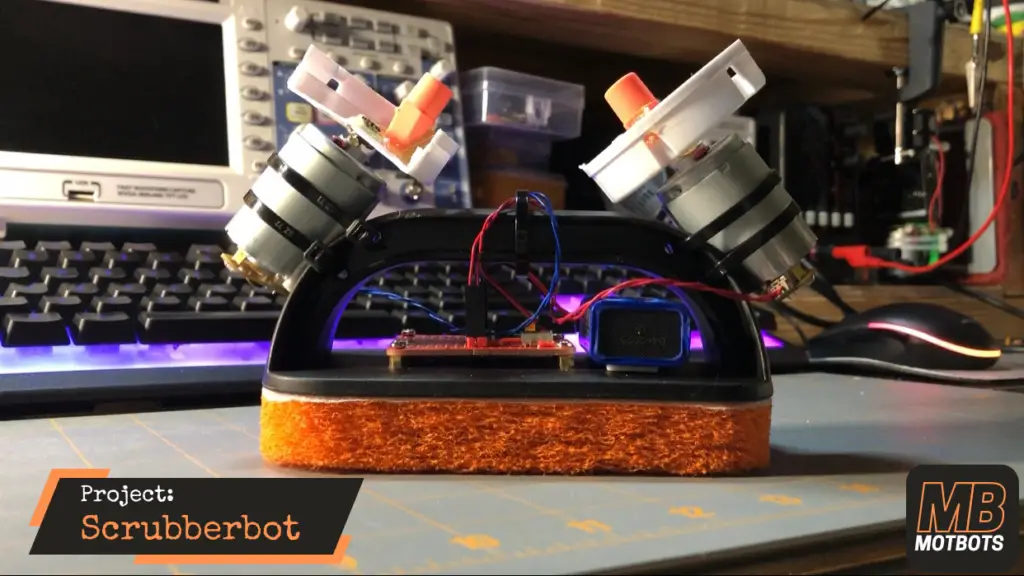

Examples of common limit switches can be found in microwaves, elevators, industrial equipment, robot vacuum cleaners, and washing machines.

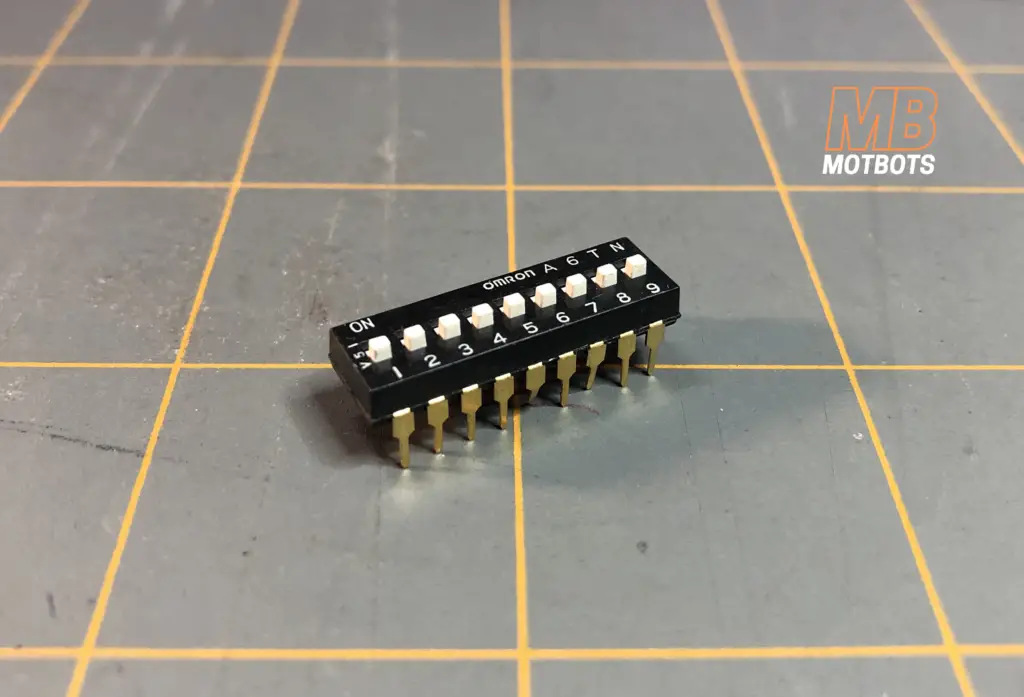

DIP Switch

DIP switches are packages of variable amounts of a series of small slide switches that are independent of one another that give the ability to control several ON/OFF positions within a circuit, such as in digital circuits.

A DIP switch stands for Dual In-Line Package — and as the name states, DIP switches are a series of of tiny switches, usually contained in a rectangular package, that provide control of the operational mode of electronic devices.

DIP switches provide a method of coding, such as in digital electronics — they give the ability to adjust settings in electrical circuits, and they have the ability to change the operational mode of electronic devices without the use of software.

The way a DIP switch works is that the array of switches in the package can be toggled ON or OFF in conformance with binary coding principles where OFF represents a “0” and ON represents a “1”.

Examples of common DIP switches are predominantly found in computing devices where digital applications are used. DIP switches are also found in older arcade games where they activate different settings for the console. DIP switches are especially common in microcontroller programmers, where one needs to adjust the DIP switch settings based on the package of microcontroller being used to program to.

Rotary Switch

A rotary switch is a switch that uses a rotating spindle or rotor to control an electronic circuit’s output.

A rotary switch allows the user to turn a knob that rotates a spindle or rotor to a variety of different positions to activate or enable different circuits within an electronic device.

As the rotary switch is rotated into different positions, wherever the spindle or rotor stops is the circuit that is activated or turned ON.

Examples of common rotary switches are often found in home appliances, industrial panels and equipment, avionics, entertainment industry equipment, and measuring equipment, such as multimeters (as seen in image above).

Want to learn more about multimeters? Check out our page titled “Multimeters in a Nutshell: What They Are, What They Can Do and How To Use Them“.

Review of Electromechanical Switch Types

| Switch Type | Actuator | Actuator Operation | Common Uses |

| Momentary Push-Button Switch | Push-Button | Actuator is momentarily pushed, then released to either open or close a circuit. | Doorbells, computer keyboard keys, intercoms, automotive ignition switches, and winch or overhead hoist switches |

| Rocker Switch | Rocker | Actuator has a seesaw effect, where it is rocked one way or the other to close or open a circuit. | Electronics devices and equipment, home lighting switches, home appliances, power tools, and industrial equipment |

| Slide Switch | Slider | Actuator has a sliding effect, where it slides one way or the other to open or close a circuit. | Electronic devices and equipment, home appliances, power tools and toys |

| Toggle Switch | Lever | Actuator is flipped back-and-forth to either open or close a circuit. | Industrial control panels, industrial machinery, avionics, marine devices, and especially automobiles in the racing industry |

| Limit Switch | Lever, plunger, roller or whisker | Works similarly to push-button switches in the sense that their actuator is pressed and released to control the action of the switch. | Microwaves, elevators, industrial equipment, robot vacuum cleaners, and washing machines |

| DIP Switch | A series of small slide switches | An array of slide switches in a package that can be toggled ON or OFF in conformance with binary coding principles. | Computing devices, older arcade consoles, and microcontroller programmers |

| Rotary Switch | Spindle or rotor | A spindle or rotor is rotated to varying positions to control separate circuits to be either active or inactive. | Home appliances, industrial panels and equipment, avionics, and entertainment industry equipment |

Conclusion

We have gone over several types of electromechanical switches and their functions, as well as their different possible configurations within this blog post. We have learned that electromechanical switches play a critical role in many, if not all circuits.

We’ve learned that electromechanical switches allow for the control of current flow through circuits by their ability to provide electrical energy to a circuit — turning a switch ON — or disconnecting electrical energy from a circuit — turning a switch OFF. There is much more to electromechanical switches and there are many other kinds of switches out in the world, but what we’ve reviewed here is what are commonly used and recognized by most people and what are used in a variety of industries.